LC-MS/MS Method Development and Validation for Quantifying Drug Concentrations in Human Plasma: A Comprehensive Guide for Clinical and Pharmaceutical Research

This article provides a comprehensive guide to the development, optimization, and validation of Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS) methods for the precise quantification of drug concentrations in human plasma.

LC-MS/MS Method Development and Validation for Quantifying Drug Concentrations in Human Plasma: A Comprehensive Guide for Clinical and Pharmaceutical Research

Abstract

This article provides a comprehensive guide to the development, optimization, and validation of Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS) methods for the precise quantification of drug concentrations in human plasma. Tailored for researchers, scientists, and drug development professionals, it covers foundational principles, practical methodological applications across various drug classes (including antibiotics, antivirals, and anticancer agents), advanced troubleshooting strategies, and rigorous validation protocols per FDA and EMA guidelines. By synthesizing the latest research and practical insights, this resource supports critical activities in therapeutic drug monitoring (TDM), pharmacokinetic studies, and clinical pharmacology, enabling enhanced analytical robustness and patient-specific therapy optimization.

LC-MS/MS Fundamentals: Principles and Role in Modern Bioanalysis

Liquid Chromatography coupled with Tandem Mass Spectrometry (LC-MS/MS) has become an indispensable technique in modern bioanalysis, particularly for the quantification of drugs and their metabolites in biological matrices such as plasma. The power of this technique lies in the synergistic combination of two powerful components: the high-resolution separation capability of High-Performance Liquid Chromatography (HPLC) and the exceptional sensitivity and specificity of the triple quadrupole mass spectrometer. This combination is especially crucial in pharmaceutical and clinical research, where precise measurement of drug concentrations is essential for pharmacokinetic studies, therapeutic drug monitoring, and bioequivalence assessments [1].

The application of LC-MS/MS for quantifying drug concentrations in plasma has revolutionized drug development by enabling researchers to detect and measure minute amounts of analytes amidst complex biological matrices. The triple quadrupole configuration, operating in Multiple Reaction Monitoring (MRM) mode, provides the selectivity required to distinguish target analytes from endogenous compounds in plasma, while the HPLC system effectively separates analytes from potential interferents prior to mass spectrometric detection [2] [3]. This article details the core components of an LC-MS/MS system and provides detailed protocols for its application in plasma drug quantification research.

Core Component 1: High-Performance Liquid Chromatography (HPLC)

Function and Role in LC-MS/MS

The HPLC system serves as the front-end separation component of the LC-MS/MS system, with the primary function of resolving the complex mixture of compounds present in biological samples like plasma. Without effective chromatographic separation, ion suppression or enhancement can occur in the mass spectrometer ion source due to co-eluting matrix components, compromising the accuracy and precision of quantification [1]. The HPLC system delivers the sample to the mass spectrometer in a purified form and in a solvent compatible with the ionization process.

A typical HPLC system for bioanalytical applications includes: a solvent delivery system (pumps), autosampler, column oven, and a analytical column. Modern systems often employ UHPLC (Ultra-High-Performance Liquid Chromatography) technology, which operates at higher pressures and uses smaller particle size columns (<2 μm) to achieve faster analysis times and improved chromatographic resolution [4] [5].

HPLC Method Parameters for Plasma Analysis

Table 1: Typical HPLC Conditions for Plasma Drug Quantification

| Parameter | Typical Specification | Application Example |

|---|---|---|

| Column Type | Reversed-Phase C18 | Ascentis Express AQ-C18 (150 × 3 mm, 5 μm) [5] |

| Column Temperature | 30-40°C | 40°C [5] |

| Mobile Phase | Aqueous buffer + Organic modifier | 0.1% Formic acid in water / Acetonitrile [4] |

| Flow Rate | 0.2-0.6 mL/min | 0.3 mL/min [5] |

| Injection Volume | 5-50 μL | 10 μL [5] |

| Gradient/Isocratic | Gradient or Isocratic elution | 100% Aqueous isocratic method [5] |

| Run Time | 3-10 minutes | 5 minutes [5] |

Core Component 2: Triple Quadrupole Mass Spectrometry

Instrument Configuration and Principle of Operation

The triple quadrupole mass spectrometer forms the detection heart of the LC-MS/MS system and is responsible for the exceptional specificity and sensitivity of the technique. As the name implies, it consists of three consecutive quadrupole mass analyzers, designated Q1 (first quadrupole), Q2 (collision cell), and Q3 (second quadrupole) [2] [3]. Each quadrupole consists of four parallel metal rods that act as mass filters by applying specific DC and RF voltages, allowing only ions of a specific mass-to-charge ratio (m/z) to pass through at any given time [1].

The analytical power of this configuration comes from the two stages of mass filtration separated by a fragmentation stage. In the first quadrupole (Q1), precursor ions (typically the protonated [M+H]+ or deprotonated [M-H]- molecules of the target analyte) are selected. These precursor ions are then transmitted to the second quadrupole (Q2), which functions as a collision cell filled with an inert gas such as nitrogen or argon. Here, the precursor ions undergo Collision-Induced Dissociation (CID), fragmenting into product ions [2] [3]. The resulting fragment ions are then analyzed in the third quadrupole (Q3), where a specific product ion is selected for detection. This two-stage mass filtering process provides unparalleled specificity for quantitative analysis [1].

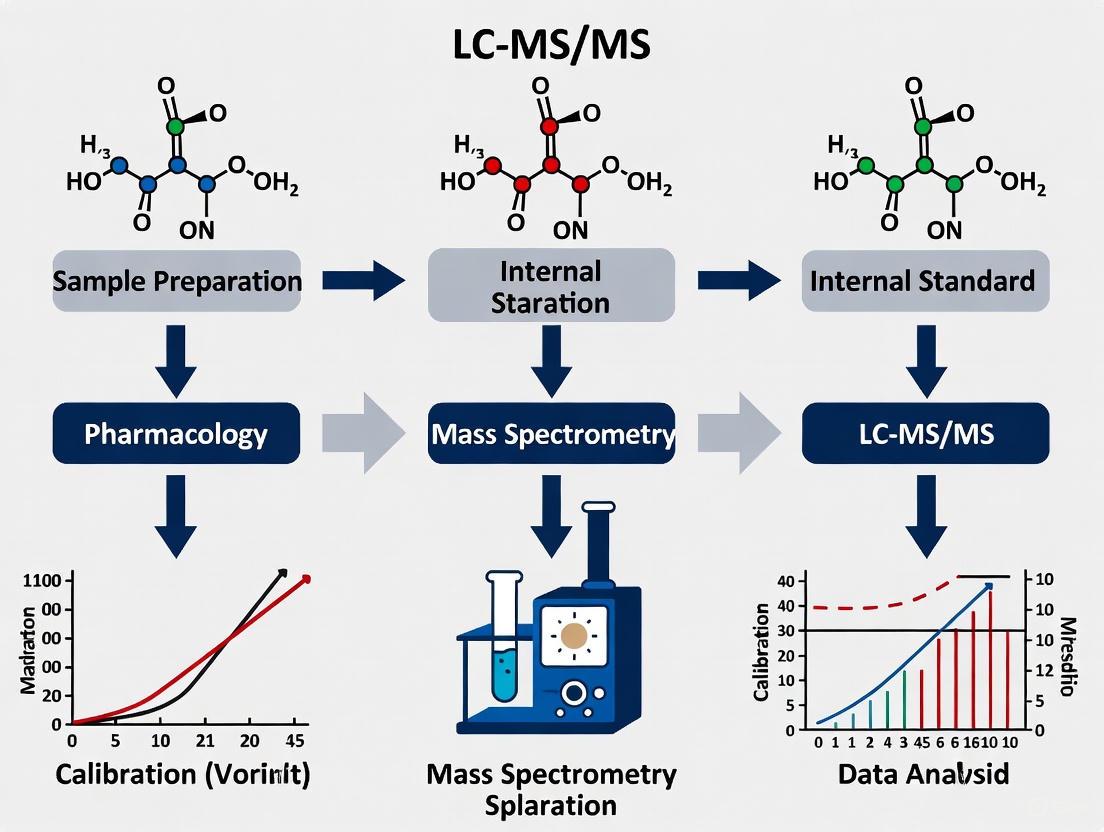

Diagram 1: LC-MS/MS System Workflow. The process begins with sample introduction and LC separation, followed by ionization, two stages of mass selection with intermediate fragmentation, and finally detection.

The interface between the HPLC and the mass spectrometer is the ionization source, which converts analyte molecules into gas-phase ions. The most common ionization techniques for bioanalytical applications are:

Electrospray Ionization (ESI): A "soft" ionization technique where the LC eluent is nebulized and charged at the tip of a metal capillary under high voltage (3-5 kV), creating a fine spray of charged droplets. As the solvent evaporates, the charge is transferred to the analyte molecules. ESI is highly effective for a wide range of polar to moderately polar molecules, including many pharmaceuticals and their metabolites [1]. It can generate both positive ions (M+H)+ and negative ions (M-H)-, with switching between modes possible within milliseconds [2].

Atmospheric Pressure Chemical Ionization (APCI): Similar to ESI, the LC eluent is nebulized, but ionization occurs in the gas phase through interactions with solvent ions created by a corona discharge. APCI is particularly useful for less polar, thermally stable compounds that do not ionize well by ESI [1].

Operational Modes and Multiple Reaction Monitoring (MRM)

The triple quadrupole mass spectrometer can operate in several different modes, but for quantitative bioanalysis of drugs in plasma, the Multiple Reaction Monitoring (MRM) mode is the gold standard [2] [3]. In MRM, both Q1 and Q3 are set to transmit specific m/z values rather than scanning across a mass range. Q1 is set to transmit the precursor ion of the target analyte, while Q3 is set to transmit a specific, characteristic product ion formed in the collision cell [1]. This dual mass filtering dramatically reduces chemical noise from the complex plasma matrix, resulting in significantly improved signal-to-noise ratios and lower limits of quantification.

Table 2: Triple Quadrupole Operational Modes

| Mode | Q1 Function | Q2 Function | Q3 Function | Primary Application |

|---|---|---|---|---|

| MRM (Multiple Reaction Monitoring) | Fixed on precursor ion | CID Fragmentation | Fixed on product ion | High-sensitivity quantification [2] [3] |

| Product Ion Scan | Fixed on precursor ion | CID Fragmentation | Scans all product ions | Structural elucidation [2] |

| Precursor Ion Scan | Scans all precursors | CID Fragmentation | Fixed on product ion | Finding all precursors that form a common fragment [2] |

| Neutral Loss Scan | Scans all precursors | CID Fragmentation | Scans with offset | Finding all precursors that lose a common neutral mass [2] |

The specificity of MRM is demonstrated by the concept of a "mass transition" - the specific precursor ion to product ion pair monitored for each analyte. For example, in a method for quantifying fosmidomycin, the mass transition monitored was m/z 181.9 → 135.9, where 181.9 is the m/z of the precursor ion and 135.9 is the m/z of the characteristic product ion used for quantification [5]. This specific transition provides a unique identifier for the target analyte, distinguishing it from other components in the plasma matrix.

Detailed Protocol: LC-MS/MS Method for Quantifying Drugs in Plasma

This protocol outlines the development and validation of an LC-MS/MS method for quantifying drug concentrations in plasma, based on established approaches in the literature [4] [5] [6].

Sample Preparation: Protein Precipitation

Protein precipitation is a simple and efficient sample clean-up technique for plasma samples.

- Aliquot Plasma Samples: Transfer 20 μL of calibration standard, quality control sample, or unknown patient sample into a microcentrifuge tube.

- Add Internal Standard: Add 80 μL of internal standard (IS) solution. The IS, typically a stable isotope-labeled analog of the analyte, corrects for variability in sample preparation and ionization efficiency [5].

- Precipitate Proteins: Add 50 μL of 10% Trichloroacetic Acid (TCA) in water. Vortex the mixture for 10 seconds to ensure complete protein precipitation [5].

- Centrifuge: Centrifuge the samples at 4°C for 20 minutes at 17,968 × g to pellet the precipitated proteins [5].

- Transfer Supernatant: Carefully transfer 80 μL of the clear supernatant to an HPLC vial for analysis. Store vials at 4°C in the autosampler until analysis.

LC-MS/MS Instrumental Analysis

HPLC Conditions:

- Column: Maintain a reversed-phase column (e.g., Biphenyl or C18, 150 × 3.0 mm, 5 μm) at 40°C [4] [5].

- Mobile Phase: Utilize a binary system. Mobile Phase A: 0.1% formic acid in water; Mobile Phase B: acetonitrile [4].

- Flow Rate: 0.3 mL/min [5].

- Injection Volume: 10 μL [5].

- Gradient Program: Implement an appropriate gradient or isocratic method. For fosmidomycin, a 100% aqueous isocratic method with 10 mM ammonium formate containing 0.1% formic acid was used with a 5-minute run time [5].

Mass Spectrometry Conditions:

- Ionization Mode: Electrospray Ionization (ESI) in positive or negative mode, optimized for the target analyte [5].

- Ion Source Parameters: Optimize temperature, nebulizer gas, and drying gas flows.

- MRM Transitions: Define the specific precursor ion → product ion transitions for the analyte and internal standard. For example, for alvocidib quantification, positive ESI mode was used with MRM [4].

- Collision Energy: Optimize the collision energy for each transition to maximize product ion signal.

Method Validation

According to regulatory guidelines (e.g., EMA), the method must be validated for [5]:

- Selectivity: Demonstrate no significant interference from blank plasma at the retention times of the analyte and IS.

- Linearity and LLOQ: Establish a calibration curve (e.g., 0.25-15 mg/L for fosmidomycin) with a Lower Limit of Quantification (LLOQ) where accuracy and precision are within ±20% [5].

- Accuracy and Precision: Evaluate intra-day and inter-day accuracy (85-115% of nominal values) and precision (CV <15%) [5].

- Matrix Effect: Assess the influence of the plasma matrix on ionization efficiency. The variability should not exceed 15% CV [5].

- Stability: Confirm analyte stability under various conditions (bench-top, freeze-thaw, long-term storage) [4].

The Scientist's Toolkit

Table 3: Essential Research Reagents and Materials for LC-MS/MS Bioanalysis

| Item | Function | Example Application |

|---|---|---|

| HPLC-grade Water/ACN | Mobile phase components | Provides clean baseline and efficient chromatography [5] |

| Formic Acid / Ammonium Formate | Mobile phase additives | Enhances analyte ionization and controls pH [5] |

| Reversed-Phase Column (C18, Biphenyl) | Analytical separation | Separates analytes from matrix interferences [4] [5] |

| Stable Isotope-Labeled Internal Standard | Quantification control | Corrects for sample prep and ionization variability [5] |

| Protein Precipitation Solvent (TCA, ACN) | Sample clean-up | Removes proteins from plasma samples [5] |

| Blank Human/Rat Plasma | Matrix for standards/QC | Maintains consistent matrix effects between samples [5] |

| KM04416 | KM04416, MF:C12H11NO3S, MW:249.29 g/mol | Chemical Reagent |

| ELA-14 (human) | ELA-14 (human), MF:C75H119N25O17S2, MW:1707.0 g/mol | Chemical Reagent |

Application in Pharmacokinetic Studies

The developed and validated LC-MS/MS method can be applied to quantify drug concentrations in plasma samples from pharmacokinetic studies. After administering the drug to subjects (human or animal), blood samples are collected at predetermined time points. The plasma is separated and processed according to the established protocol [4] [5]. The resulting concentration-time data allows researchers to calculate critical pharmacokinetic parameters such as C~max~, T~max~, AUC, and half-life, which are essential for understanding the drug's absorption, distribution, metabolism, and excretion (ADME) profile [4]. For instance, an LC-MS/MS method was successfully applied to study the tissue distribution of alvocidib in rats, revealing differential distribution of the parent drug and its glucuronide metabolite across various tissues [4].

The LC-MS/MS system, with its core components of HPLC for separation and triple quadrupole mass spectrometry for detection, provides an exceptionally powerful platform for the quantification of drugs in plasma. The robustness, sensitivity, and specificity offered by this technology, particularly when operated in MRM mode, make it the method of choice in modern bioanalytical laboratories supporting drug development and clinical research. The detailed protocols and guidelines presented in this application note provide a framework for researchers to develop and implement reliable LC-MS/MS methods for their pharmacokinetic and bioanalysis studies.

This application note details the synergistic combination of Electrospray Ionization (ESI) and Multiple Reaction Monitoring (MRM) for achieving superior sensitivity in the quantification of drug concentrations in plasma. Within the context of LC-MS/MS method development, this targeted proteomics approach provides the high selectivity and robust quantification necessary for critical applications in drug development, such as pharmacokinetic studies and therapeutic drug monitoring. We summarize key performance data, provide detailed experimental protocols, and visualize the underlying mechanisms that make this technology a cornerstone of modern bioanalysis.

The quantification of low-abundance therapeutics and biomarkers in complex biological matrices like plasma presents a significant analytical challenge due to the wide dynamic range of protein concentrations and the presence of interfering substances. While immunoassays have traditionally been used, they are often expensive, time-consuming to develop, and lack multiplexing capabilities [7]. Liquid chromatography coupled with tandem mass spectrometry (LC-MS/MS) operating in MRM mode, with ESI as the ionization source, has emerged as a powerful alternative. The dual mass filtering inherent to MRM on a triple quadrupole mass spectrometer, combined with the efficient ion production of ESI for liquid samples, creates a highly specific and sensitive platform for quantitative analysis [8]. This note explores the mechanisms behind this sensitivity and provides a practical framework for its application in plasma drug quantification.

Fundamental Mechanisms and Key Enhancements

Principles of ESI and MRM

The sensitivity of the combined ESI-MRM platform stems from its coherent multi-stage process:

Electrospray Ionization (ESI): ESI functions as a critical front-end, efficiently generating gas-phase ions from the liquid chromatographic eluent at atmospheric pressure. It is particularly adept at ionizing a wide range of biomolecules, including peptides and drugs, making it ideal for bioanalysis [9]. The production of multiple-charged ions further enhances detection capabilities for larger molecules.

Multiple Reaction Monitoring (MRM): MRM on a triple quadrupole mass spectrometer provides exceptional specificity through two stages of mass selection. The first quadrupole (Q1) selects a specific precursor ion corresponding to the target analyte. This ion is then fragmented in the second quadrupole (Q2) via collision-induced dissociation, and a unique product ion is selected in the third quadrupole (Q3) for detection. This specific pair of precursor and product ions is known as a "transition" [7] [8]. By monitoring this transition, the method effectively filters out chemical noise from the complex plasma matrix, leading to a significant gain in signal-to-noise ratio and, consequently, sensitivity.

Technological Advances for Enhanced Sensitivity

A major bottleneck for SRM/MRM technology has been insufficient sensitivity for detecting low-abundance proteins or drugs, which can be present at low ng/mL to pg/mL concentrations in plasma [7]. Recent advances have directly addressed this challenge:

Ion Funnel Technology: The introduction of a multi-capillary inlet/dual-stage electrodynamic ion funnel interface has dramatically enhanced ion transmission efficiency from the ESI source to the mass analyzer. This innovation has been shown to increase average SRM peak intensities by approximately 70-fold and improve the limit of detection for peptides by about 10-fold in complex matrices like mouse plasma [10]. This enhancement allows for the detection of proteins in the 40 to 80 ng/mL range without the need for extensive front-end sample fractionation [10].

Front-End Sample Processing: To further improve sensitivity, various sample preparation strategies are employed to reduce matrix complexity and enrich target analytes. These include:

- Immunoaffinity Depletion: Removal of high-abundance plasma proteins to reveal lower-abundance targets [7].

- Fractionation: Techniques like strong cation exchange (SCX) chromatography to simplify the sample [7].

- Targeted Enrichment: Using antibodies to selectively isolate specific proteins or peptides of interest, which can push quantification limits to the low ng/mL range [7].

The logical relationship and workflow integrating these components for superior sensitivity are illustrated below.

Sensitivity Enhancement Workflow in LC-ESI-MRM

Quantitative Performance Data

The following table summarizes reported limits of quantification (LOQ) for targeted proteins in blood plasma and serum using different SRM/MRM strategies, demonstrating the impact of various sensitivity-enhancement approaches.

Table 1: Reported Limits of Quantification (LOQ) in Plasma/Serum Using SRM/MRM

| Instrumentation Platform | Enrichment Method | Reported LOQ | Reference |

|---|---|---|---|

| NanoLC-SRM with standard interface | None | ~1 μg/mL | [7] |

| NanoLC-SRM with standard interface | None | 15-168 ng/mL | [7] |

| LC-SRM with dual ion funnel interface | None | 40-80 ng/mL | [10] |

| LC-SRM (various platforms) | Immunoaffinity depletion & fractionation | Low ng/mL range | [7] |

Experimental Protocol: MRM-Based Quantification of a Drug in Plasma

This protocol outlines a generalized procedure for developing and applying an LC-ESI-MRM method for quantifying a small molecule drug in plasma, incorporating best practices for achieving high sensitivity.

Sample Preparation

Protein Precipitation:

- Thaw plasma samples on ice and centrifuge at 10,000 × g for 5 minutes.

- Aliquot 100 μL of plasma into a microcentrifuge tube.

- Add 300 μL of ice-cold acetonitrile (containing a stable isotope-labeled internal standard for the target drug) to precipitate proteins.

- Vortex vigorously for 60 seconds and incubate at -20°C for 10 minutes.

- Centrifuge at 15,000 × g for 15 minutes at 4°C.

- Transfer the clear supernatant to a new tube and evaporate to dryness under a gentle stream of nitrogen at 40°C.

- Reconstitute the dried extract in 100 μL of initial LC mobile phase (e.g., 95% water, 5% methanol, 0.1% formic acid). Vortex and centrifuge before transfer to an LC vial.

Alternative/Additional Enrichment (for very low abundances):

- For targets expected to be in the low ng/mL range or lower, implement immunoaffinity enrichment using antibody-coated magnetic beads specific to the target drug or peptide, following the manufacturer's protocol [7].

- Solid-phase extraction (SPE) can also be used for further cleanup and concentration.

LC-ESI-MRM Method Configuration

Liquid Chromatography:

- Column: Reversed-phase C18 column (e.g., 2.1 mm x 100 mm, 1.8 μm particle size).

- Mobile Phase A: Water with 0.1% formic acid.

- Mobile Phase B: Acetonitrile or Methanol with 0.1% formic acid.

- Gradient: Optimize a linear gradient from 5% B to 95% B over 10-15 minutes, followed by a wash and re-equilibration.

- Flow Rate: 0.2 - 0.4 mL/min.

- Column Temperature: 40°C.

Mass Spectrometry (Triple Quadrupole):

- Ion Source: Electrospray Ionization (ESI), positive or negative mode, depending on the analyte.

- Source Parameters: Optimize capillary voltage, cone voltage, desolvation temperature, and gas flows for maximum precursor ion signal.

- Ion Funnel Interface: If available, ensure the dual-stage ion funnel is operational for enhanced sensitivity [10].

- MRM Transitions:

- For the target drug, select 2-3 specific precursor ion > product ion transitions.

- Q1: Select the intact precursor ion ([M+H]+ or [M-H]-) of the drug.

- Q2 (CID): Optimize collision energy for each transition to generate a abundant, characteristic product ion.

- Q3: Select the most intense and specific product ion for quantification, and 1-2 additional ions for qualification.

- Follow the same process for the stable isotope-labeled internal standard.

Table 2: The Scientist's Toolkit - Essential Research Reagents and Materials

| Item/Category | Function and Importance |

|---|---|

| Stable Isotope-Labeled Internal Standards | Corrects for sample prep variability and ion suppression; essential for accurate quantification. |

| Immunoaffinity Depletion Columns | Removes high-abundance plasma proteins (e.g., albumin) to reduce dynamic range and reveal low-abundance targets. |

| Anti-target Antibody Beads | Selectively enriches the specific drug or protein target from plasma, drastically improving LOQ. |

| Triple Quadrupole Mass Spectrometer | The core platform for MRM, providing the two stages of mass selection for high specificity and sensitivity. |

| Ion Funnel Interface | Dramatically improves ion transmission into the mass spectrometer, boosting signal intensity [10]. |

The following diagram maps the logical decision process for method development based on the required sensitivity for the target analyte.

Method Selection Based on Sensitivity Needs

The integration of Electrospray Ionization with Multiple Reaction Monitoring mass spectrometry represents a powerful solution for the sensitive and specific quantification of drugs in plasma. The fundamental mechanisms of MRM provide unparalleled selectivity, while advancements in ESI interface technology, particularly the ion funnel, have driven substantial gains in sensitivity. By following the detailed protocols and strategic method development outlined in this application note, researchers can reliably detect and quantify target analytes at clinically relevant concentrations, thereby accelerating drug development and biomarker validation.

The Critical Role in Therapeutic Drug Monitoring (TDM) and Pharmacokinetic/Pharmacodynamic (PK/PD) Studies

Therapeutic Drug Monitoring (TDM) and Pharmacokinetic/Pharmacodynamic (PK/PD) studies are critical disciplines in modern clinical pharmacology and drug development. TDM is the clinical practice of measuring specific drugs at designated intervals to maintain a constant concentration in a patient's bloodstream, thereby optimizing individual dosage regimens [11]. It is particularly vital for drugs with narrow therapeutic ranges, marked pharmacokinetic variability, medications where target concentrations are difficult to monitor, and drugs known to cause both therapeutic and adverse effects [11]. The process is predicated on the assumption that a definable relationship exists between dose and plasma drug concentration, and between concentration and therapeutic effects [11].

The integration of PK/PD modeling has revolutionized drug development by providing a mathematical approach to study the time course of drug effects and exposure-response relationships [12]. Liquid Chromatography with Tandem Mass Spectrometry (LC-MS/MS) has emerged as a cornerstone analytical technology in this field, offering the sensitivity, specificity, and versatility required for accurate drug quantification in complex biological matrices like plasma [13] [14]. This article delineates the application of LC-MS/MS within TDM and PK/PD studies, providing detailed protocols and frameworks for researchers and drug development professionals.

Theoretical Foundations of TDM and PK/PD

Pharmacokinetics (PK) and Pharmacodynamics (PD): Core Concepts

Pharmacokinetics (PK) describes the journey of a drug through the body, encompassing the processes of Absorption, Distribution, Metabolism, and Excretion (ADME) [15]. PK parameters such as total drug exposure (Area Under the Curve, AUC), maximum blood concentration (Cmax), half-life (t1/2), and elimination rate (Ke) are fundamental for determining dosing regimens [16].

Pharmacodynamics (PD), in contrast, is the study of the biological and physiological effects of a drug on the body, including its mechanism of action and the relationship between drug concentration and effect [15]. Key PD parameters include the maximum effect (Emax) and the concentration that produces 50% of the maximum effect (EC50) [16].

The interplay between PK and PD is pivotal. PK/PD modeling integrates data from both fields to predict dosing strategies and therapeutic outcomes, ensuring developed drugs have the highest efficacy and lowest risk of adverse effects [15]. The relationship between drug concentration and effect is often described by the sigmoid Emax model, which has its origins in receptor theory and defines a maximal effect (Emax) for a drug [17].

The Essential Role of Therapeutic Drug Monitoring

TDM enables the individualization of therapy by leveraging the relationship between drug exposure and clinical response. Its indications have widened to include assessing efficacy, verifying compliance, detecting drug-drug interactions, avoiding toxicity, and monitoring therapy cessation [11]. The multidisciplinary TDM process, outlined in Table 1, requires excellent communication among team members to ensure best practices.

Table 1: Key Indications for Therapeutic Drug Monitoring

| Indication | Clinical Application Example |

|---|---|

| Optimizing Efficacy | Tailoring dosage of prophylactic drugs like lithium or cyclosporine to prevent disease recurrence or transplant rejection [11]. |

| Avoiding Toxicity | Diagnosing digoxin toxicity, which can mimic heart disease symptoms, by confirming elevated plasma concentrations [11]. |

| Assessing Compliance | Differentiating between poor compliance and undertreatment when a low drug concentration is observed [11]. |

| Managing Drug Interactions | Adjusting lithium dosage when a thiazide diuretic is co-administered, or adjusting theophylline when erythromycin is added [11]. |

| Dosing in Special Populations | Optimizing doses in critically ill patients or those with organ dysfunction where PK parameters are altered [14] [11]. |

LC-MS/MS as the Analytical Gold Standard

The choice of analytical technique is fundamental to successful TDM and PK/PD studies. LC-MS/MS offers increased sensitivity and specificity compared to other methods like immunoassays, and is often the only viable method for quantifying drugs without natural chromophores or fluorophores [13].

Advantages of LC-MS/MS in Bioanalysis

- High Sensitivity and Specificity: The combination of chromatographic separation with mass spectrometric detection minimizes interference from matrix effects and drug metabolites, leading to highly accurate measurements [13] [14].

- Wide Applicability: LC-MS/MS can be applied to a vast range of small molecules and some large molecules, making it suitable for monitoring diverse drug classes, from antibiotics to oral antitumor agents [14] [18].

- Multiplexing Capability: Methods can be developed to simultaneously quantify dozens of drugs, as demonstrated by an assay that measures 57 oral antitumor agents in a single run, improving efficiency for clinical studies [18].

- Rapid Analysis: Modern LC-MS/MS systems can achieve total run times as low as 5 minutes per sample, facilitating high-throughput analysis crucial for clinical decision-making [14].

Application Notes: Implementing LC-MS/MS in TDM and PK/PD Studies

Protocol: LC-MS/MS Method Development and Validation for Omadacycline

The following detailed protocol, adapted from a recent study, outlines the steps for developing and validating a robust LC-MS/MS method for quantifying the antibiotic omadacycline in human plasma [14].

Instruments and Reagents

- Liquid Chromatograph: Agilent 1260 series HPLC system.

- Mass Spectrometer: API 4000 triple quadrupole tandem mass spectrometer.

- Chromatography Column: Phenomenex KINETEX XB-C18 (2.6 μm, 3 × 50 mm).

- Mobile Phases: (A) 0.1% formic acid in water; (B) pure acetonitrile.

- Chemicals: Omadacycline benzenesulfonate (reference standard), fexofenadine-d6 (Internal Standard), HPLC-grade methanol, acetonitrile, and formic acid.

Sample Preparation Procedure

- Protein Precipitation: Add 200 μL of protein precipitant (acetonitrile containing internal standard, fexofenadine-d6 at 50 ng/mL) to 50 μL of plasma sample.

- Mixing and Centrifugation: Vortex the mixture vigorously for 5 minutes and centrifuge at 13,000 rpm for 5 minutes at 4°C.

- Dilution: Transfer 50 μL of the supernatant to 200 μL of 0.1% formic acid in water and vortex to mix.

- Injection: Transfer 100 μL of the final supernatant to an injection vial and inject 5 μL into the LC-MS/MS system.

Chromatographic and Mass Spectrometric Conditions

- Gradient Elution: Total run time of 5 minutes at a flow rate of 0.4 mL/min.

- Gradient Program:

- 0-0.5 min: 10% B

- 0.5-3.5 min: 10% B → 90% B

- 3.5-4.0 min: 90% B

- 4.0-5.0 min: 10% B

- Ionization: Electrospray Ionization (ESI) in positive ion mode.

- Detection: Multiple Reaction Monitoring (MRM) with transitions:

- Omadacycline: m/z 557.4 → 453.4

- Internal Standard (fexofenadine-d6): m/z 508.4 → 472.8

Method Validation Results

The method was rigorously validated according to scientific guidelines, with key results summarized in Table 2 below.

Table 2: LC-MS/MS Method Validation Parameters for Omadacycline Quantification

| Validation Parameter | Result / Acceptance Criterion |

|---|---|

| Linear Range | 20 - 2000 ng/mL (effectively covers >98% of clinical samples) [14] |

| Intra-day & Inter-day Precision | Relative Standard Deviation (RSD) < 10% [14] |

| Accuracy | Relative Error (RE) within ± 10.00% [14] |

| Selectivity | No interference from blank plasma matrices at analyte retention times [14] |

| Carryover | Peak area at analyte position <20% of the LLOQ [14] |

Workflow Diagram: LC-MS/MS in TDM and PK/SD

The following diagram illustrates the integrated workflow of TDM and PK/PD studies, from clinical assessment to data-informed dosing recommendations.

Integrating PK/PD Modeling in Drug Development

PK/PD modeling is an indispensable tool that evolves throughout the drug discovery and development process [19] [12]. Its primary objective is to select promising compounds and identify safe, effective doses and dosing regimens [19].

A Framework for PK/PD Study Design

Effective implementation requires a strategic, iterative approach, as outlined below.

Key Considerations for PK/PD Study Design

- Effective Partnerships: A core partnership between pharmacologists and DMPK (Drug Metabolism and Pharmacokinetics) scientists must be established early in a discovery program [19].

- Pilot Studies: Initial studies with a reference compound help establish fundamental PK/PD principles, optimize the study design, and build confidence before testing novel compounds [19].

- Study Types: Studies progress from simple, acute models (single dose, sparse sampling) to complex, chronic disease models (repeated dosing, multiple biomarkers) as the program matures [19].

- Graphical Data Evaluation: Plotting concentration and response versus time, and response versus concentration, is crucial for identifying relationships, delays (hysteresis), and potential biases from dropout [17].

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful execution of LC-MS/MS-based TDM and PK/PD studies relies on a suite of essential materials and reagents. The following table details key components.

Table 3: Essential Research Reagents and Materials for LC-MS/MS-based TDM/PK/PD

| Item | Function & Application |

|---|---|

| Triple Quadrupole Mass Spectrometer | Gold standard for quantitative LC-MS/MS; enables highly specific Multiple Reaction Monitoring (MRM) for precise drug quantification [13] [14]. |

| U/HPLC System with C18 Column | Provides high-resolution chromatographic separation of the analyte from matrix components, reducing ion suppression and improving data quality [14] [18]. |

| Certified Reference Standard | The authentic drug substance of known purity and identity; essential for accurate calibration and quantification [14]. |

| Stable Isotope-Labeled Internal Standard | (e.g., fexofenadine-d6, deuterated analogs). Corrects for variability in sample preparation and ionization efficiency, improving precision and accuracy [13] [14]. |

| HPLC-Grade Solvents & Modifiers | (e.g., Acetonitrile, Methanol, Formic Acid). Used for mobile phases and sample preparation; high purity is critical to minimize background noise and contamination [14]. |

| Blank Control Matrix | (e.g., Drug-free human plasma). Used to prepare calibration standards and quality control samples for method development and validation [14] [18]. |

| Protein Precipitation Plates/Tubes | Facilitate high-throughput sample preparation by removing proteins from plasma samples, clarifying the extract for LC-MS/MS analysis [14]. |

| MMV665916 | MMV665916, MF:C19H19N3O4, MW:353.4 g/mol |

| BMS-986020 sodium | BMS-986020 sodium, MF:C29H25N2NaO5, MW:504.5 g/mol |

The synergy between robust LC-MS/MS analytical methods, principled Therapeutic Drug Monitoring, and sophisticated PK/PD modeling forms the bedrock of modern precision medicine in pharmacology. The protocols and frameworks detailed in this article provide a roadmap for researchers to generate high-quality, clinically actionable data. As drug therapies become more complex and targeted, the role of LC-MS/MS in elucidating exposure-response relationships and guiding individualized treatment will only grow in importance, ultimately contributing to the development of safer and more effective pharmaceuticals.

Liquid chromatography coupled with tandem mass spectrometry (LC-MS/MS) has emerged as a cornerstone technology in bioanalytical chemistry, particularly for the precise quantification of drug concentrations in plasma. This application note delineates the distinct advantages of LC-MS/MS over traditional High-Performance Liquid Chromatography (HPLC) with conventional detectors (e.g., UV, fluorescence) in the context of modern drug development. We focus on three pivotal areas where LC-MS/MS offers transformative benefits: superior selectivity, enhanced sensitivity, and powerful multiplexing capability. Supported by experimental data and detailed protocols, this document provides a framework for researchers and scientists to leverage these advantages in pharmacokinetic studies, therapeutic drug monitoring, and bioequivalence assessments.

Comparative Advantages of LC-MS/MS

The transition from HPLC to LC-MS/MS represents a significant evolution in analytical capabilities, driven by the mass spectrometer's role as a highly specific detector.

Table 1: Key Advantages of LC-MS/MS over Traditional HPLC

| Feature | Traditional HPLC | LC-MS/MS | Impact on Plasma Drug Analysis |

|---|---|---|---|

| Selectivity | Relies on retention time and spectral matching; susceptible to co-eluting interferents from complex matrices. | Uses mass-to-charge ratio (m/z) and unique fragmentation patterns; effectively distinguishes analytes from matrix components. [1] [20] | Reduces false positives/negatives; enables accurate quantification in complex biomatrices like plasma without complete baseline separation. |

| Sensitivity | Typically in the ng-µg/mL range (e.g., UV detection). | Routinely achieves pg-ng/mL levels (e.g., 0.004-0.01 ng/injection LLOQ reported). [21] [22] | Essential for quantifying low-dose drugs, metabolites, and drugs with low circulating plasma concentrations. |

| Multiplexing | Limited; typically requires separate methods or compromised conditions for multiple analytes. | Enables simultaneous quantification of dozens of analytes in a single run via Multiple Reaction Monitoring (MRM). [1] [23] | Dramatically increases throughput for therapeutic drug monitoring (TDM) and pharmacokinetic studies; allows for comprehensive cocktail analysis. |

The following diagram illustrates the core logical relationship underpinning the superior performance of LC-MS/MS in bioanalysis.

LC-MS/MS Specificity Logic

Enhanced Selectivity via Tandem MS

The selectivity of LC-MS/MS stems from its use of tandem mass spectrometry. The first mass analyzer (MS1) selects the intact ion (precursor ion) of the target analyte. This ion is then fragmented in a collision cell, and a second mass analyzer (MS2) selects a unique product ion. This two-stage filtering process, monitored as a precursor-product ion transition, provides a high degree of certainty in analyte identity that is unattainable with HPLC retention time alone. [1] This is crucial in plasma analysis, where endogenous compounds can co-elute and interfere with the analyte of interest.

Superior Sensitivity

LC-MS/MS offers significantly lower limits of quantification (LLOQ) compared to HPLC. This is due to the high efficiency of modern ionization sources like electrospray ionization (ESI) and the reduced chemical noise inherent in the MRM detection mode. [1] [22] For instance, a recently developed method for vonoprazan, amoxicillin, and clarithromycin in human plasma achieved LLOQs of 2-5 ng/mL, with detection limits (LOD) as low as 0.0013 ng/injection, demonstrating sensitivity suitable for rigorous pharmacokinetic studies. [21] Furthermore, techniques like micro-flow LC-MS/MS can offer additional sensitivity gains by improving ionization efficiency. [24]

High-Throughput Multiplexing

The MRM capability of triple quadrupole mass spectrometers allows for the rapid toggling between dozens, or even hundreds, of specific ion transitions within a single chromatographic run. [1] This enables the simultaneous quantification of a vast panel of drugs. A prominent example is a multiplex assay for 14 antibacterial and antifungal agents in patient serum, which streamlines therapeutic drug monitoring in intensive care units without compromising accuracy or precision. [23] This multiplexing capability drastically improves laboratory efficiency and reduces sample volume requirements.

Application Protocol: Multiplex Quantification of Antibacterial Agents in Plasma

The following detailed protocol is adapted from a validated method for the simultaneous quantification of 14 antibacterial/antifungal drugs in human serum, exemplifying the practical application of LC-MS/MS advantages in a clinical research setting. [23]

Research Reagent Solutions

Table 2: Essential Materials and Reagents

| Item | Function/Description | Example |

|---|---|---|

| Analytical Column | Core separation unit; a reversed-phase C8 column (e.g., 1.7 µm, 2.1 x 50 mm) provides robust separation for a diverse drug panel. [23] | Waters Acquity UPLC C8 |

| Mass Spectrometer | Detection and quantification; a triple quadrupole mass spectrometer operated in MRM mode is the industry standard. [1] [23] | Shimadzu LCMS-8050 |

| Internal Standards | Correct for variability in sample preparation and ionization; stable isotope-labeled analogs of the analytes are ideal. [23] | d5-piperacillin, 13C2,2H3-voriconazole |

| Sample Solvent | Protein precipitation agent; organic solvent with acid modifier to efficiently denature and precipitate plasma proteins. [23] | Methanol with 0.1% Formic Acid |

| Mobile Phase | A: Aqueous buffer with volatile modifier (e.g., 0.1% formic acid). B: Organic solvent with same modifier (e.g., acetonitrile with 0.1% formic acid). [21] [23] | 0.1% Formic Acid in Water / 0.1% Formic Acid in Acetonitrile |

Experimental Workflow

The following diagram outlines the end-to-end workflow for the multiplex assay, from sample collection to data analysis.

Multiplex Assay Workflow

Sample Preparation Protocol

- Protein Precipitation: Transfer 100 µL of thawed plasma or serum into a polypropylene tube.

- Internal Standard Addition: Add 20 µL of a mixed internal standard solution.

- Precipitation: Add 480 µL of ice-cold methanol containing 0.1% formic acid to precipitate proteins.

- Vortex and Centrifuge: Vortex the mixture vigorously for 1 minute, then centrifuge at 13,780 × g for 8 minutes.

- Supernatant Collection: Transfer 500 µL of the clear supernatant to an LC vial for analysis.

Chromatographic Conditions

- Column: Waters Acquity UPLC C8 (1.7 µm, 2.1 mm × 50 mm)

- Column Temperature: 40 °C

- Mobile Phase: A: 0.1% Formic acid in water; B: 0.1% Formic acid in acetonitrile

- Flow Rate: 0.4 mL/min

- Injection Volume: 2 µL

- Gradient Program:

Time (min) %B 0.0 5 0.5 5 4.0 65 4.2 5 5.0 5

Mass Spectrometric Conditions

- Ionization Source: Electrospray Ionization (ESI)

- Ion Mode: Positive

- Detection Mode: Multiple Reaction Monitoring (MRM)

- Operation: The mass spectrometer is configured to monitor specific precursor ion → product ion transitions for each of the 14 target analytes and their internal standards. Source temperature, desolvation gas, and collision energies are optimized for maximum response.

Method Validation Data

The described method was rigorously validated, yielding the following performance characteristics for key analytes. [23]

Table 3: Validation Data for Select Antibacterial Agents

| Analyte | Linear Range (µg/mL) | LLOQ (µg/mL) | Intra-day Precision (%RSD) | Inter-day Precision (%RSD) | Accuracy (%RE) | Absolute Recovery (%) |

|---|---|---|---|---|---|---|

| Linezolid | 0.1 - 100 | 0.1 | < 6.2 | < 8.5 | ± 8.9 | > 95 |

| Vancomycin | 0.3 - 100 | 0.3 | < 7.1 | < 9.3 | ± 11.2 | > 93 |

| Meropenem | 0.1 - 50 | 0.1 | < 8.5 | < 10.1 | ± 9.8 | > 94 |

| Voriconazole | 0.1 - 100 | 0.1 | < 5.9 | < 7.7 | ± 7.5 | > 96 |

LC-MS/MS solidly outperforms traditional HPLC for the quantification of drugs in plasma by providing unmatched selectivity to eliminate matrix interferences, exceptional sensitivity to monitor low-abundance analytes, and unparalleled multiplexing capability for high-throughput analysis. The detailed protocol for a 14-plex antibacterial assay serves as a practical template for researchers to implement this powerful technology. As instrument innovation continues, with trends toward miniaturization, increased automation, and greener chemistry, the role of LC-MS/MS as an indispensable tool in drug development and clinical research is poised for further growth. [25] [26] [22]

From Theory to Practice: Developing Robust LC-MS/MS Methods for Diverse Drug Classes

The development of robust, sensitive, and selective bioanalytical methods is a critical pillar in pharmaceutical research, particularly for the quantification of drug concentrations in plasma using Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS). The reliability of pharmacokinetic data, essential for therapeutic drug monitoring and dose regimen optimization, hinges directly on the meticulous optimization of two foundational elements: the chromatographic column and the mobile phase [27] [14]. Within the complex matrix of plasma, where analytes are present at trace levels amidst a host of interfering compounds, a well-designed chromatographic separation is the first and most crucial step in ensuring data integrity. This application note provides a detailed, practical framework for the selection and optimization of columns and mobile phases, framed within the context of developing an LC-MS/MS method for drug quantification in plasma.

Core Principles and Systematic Protocol

A structured approach to method development significantly reduces the time and resources required to achieve a validated method. The following sections outline a step-by-step protocol for column screening and mobile phase optimization.

Step-by-Step Column Selection Protocol

The choice of column dictates the primary interaction mechanism with your analyte and is the starting point for method development.

1. Define the Goal: Clearly outline the method's requirements, including desired resolution of critical pairs, sensitivity (LLOQ), analysis time, and robustness. 2. Analyze Analyte Structure: Determine the analyte's hydrophobicity, ionization constants (pKa), and presence of specific functional groups to guide the selection of separation mode [28]. 3. Select the Chromatographic Mode: - Reversed-Phase (RPLC): The most common mode for LC-MS/MS of small molecule drugs. Ideal for neutral and non-polar to moderately polar compounds [27] [29]. - Hydrophilic Interaction Liquid Chromatography (HILIC): Employ for highly polar and hydrophilic compounds that are not retained in RPLC [29]. 4. Screen Initial Columns: Begin with 3-4 columns featuring different stationary phase chemistries. A typical screening set may include: - A C18 column (e.g., Phenomenex KINETEX XB-C18 [14] or equivalent). - A Phenyl-Hexyl or equivalent for potential π-π interactions. - A Polar-embedded phase (e.g., amide) for improved retention of polar compounds. - A HILIC column (e.g., silica or amide) if RPLC retention is insufficient. 5. Evaluate Performance: Assess columns based on peak shape (asymmetry factor), retention factor (k), and resolution of critical analyte pairs from potential interferences. The column providing the best compromise of these factors is selected for further mobile phase optimization.

Table 1: Guide to Reversed-Phase Column Selection Based on Analyte Properties

| Analyte Property | Recommended Stationary Phase | Rationale |

|---|---|---|

| Non-polar to moderate polarity | C18 or C8 | Provides strong hydrophobic retention; the workhorse for most drug analyses [14] [30]. |

| Polar compounds | Polar-embedded (e.g., amide, ether) | Offers mixed-mode retention; can improve peak shape for bases [28]. |

| Aromatic compounds | Phenyl or Phenyl-Hexyl | Potential for π-π interactions, offering different selectivity versus C18. |

| Basic compounds | * charged surface hybrid (CSH) * or base-deactivated | Minimizes silanol interactions, reducing peak tailing and improving sensitivity [28]. |

| Very Polar/ Hydrophilic | HILIC | Provides complementary retention mechanism to RPLC; uses organic-rich mobile phases [29]. |

Comprehensive Mobile Phase Optimization

The mobile phase serves not only to elute analytes but also to control ionization, selectivity, and compatibility with the MS detector.

1. Select Organic Modifier: Choose between acetonitrile (ACN) and methanol (MeOH). Acetonitrile is generally preferred for LC-MS due to its lower viscosity (reducing backpressure), better UV transparency, and superior peak shape. Methanol is a cost-effective alternative but can generate higher backpressure [28] [31]. 2. Adjust pH with Volatile Buffers: The mobile phase pH is critical for controlling the ionization state of ionizable analytes, thereby modulating retention and selectivity. For LC-MS, always use volatile buffers such as ammonium formate or ammonium acetate, typically in a concentration range of 2-10 mM [32] [28] [30]. Set the pH at least 1.5–2.0 units away from the analyte's pKa to ensure a consistent ionization state and minimize retention time drift [28]. 3. Incorporate Additives: Small amounts of acidic or basic modifiers can significantly enhance ionization efficiency and peak shape. - Formic Acid (0.05-0.1%): Standard additive for positive electrospray ionization (ESI+), promotes [M+H]+ formation [14] [32]. - Ammonium Hydroxide / Ammonia Solution: Used for negative electrospray ionization (ESI-) to promote [M-H]- formation. - Trifluoroacetic Acid (TFA): Avoid if possible in LC-MS. While it excellent for peak shape of basic compounds, it causes severe ion suppression in the MS detector [28]. 4. Optimize Elution Mode: - Isocratic Elution: Suitable for simple mixtures where the retention of all components is similar. - Gradient Elution: Essential for complex samples or when analytes have a wide range of polarities. A gradient, typically from a low to a high percentage of organic solvent, ensures all compounds are eluted with sharp peaks and in a reasonable time [27] [14] [30]. 5. Fine-tune Flow Rate and Temperature: The flow rate (e.g., 0.3-0.6 mL/min for standard 2.1 mm i.d. columns) and column temperature (e.g., 40-50°C) are final parameters for fine-tuning resolution and cycle time. Higher temperatures can reduce backpressure and improve efficiency [14] [30].

Table 2: Optimization of Mobile Phase Additives for LC-MS/MS Applications

| Additive | Typical Concentration | Primary Function & ESI Mode | Advantages | Considerations |

|---|---|---|---|---|

| Formic Acid | 0.05 - 0.1% | Promotes protonation; ESI+ [14] [32] | Volatile, excellent for [M+H]+ signal, widely used. | Can suppress signal in ESI-; may not be strong enough for some basic compounds. |

| Ammonium Formate | 2 - 10 mM | pH control; ESI+ & ESI- [32] [30] | Volatile, good buffer capacity at ~pH 3-4. | Can form [M+NH4]+ adducts in ESI+, complicating spectra. |

| Ammonium Acetate | 2 - 10 mM | pH control; ESI+ & ESI- [32] | Volatile, good buffer capacity at ~pH 4.5-5.5. | Less common for ESI+; suitable for neutral molecules and ESI-. |

| Acetic Acid | 0.05 - 0.5% | Promotes protonation; ESI+ [32] | Weaker acid than formic acid; can offer different selectivity. | May provide lower sensitivity for some compounds compared to formic acid. |

| Ammonia / Ammonium Hydroxide | 0.05 - 0.2% | Promotes deprotonation; ESI- [30] | Volatile, essential for many ESI- applications. | Highly volatile, requires careful mobile phase preparation. |

Experimental Protocols and Methodologies

Detailed Protocol: Mobile Phase Optimization for a Novel Drug Compound

This protocol outlines the experimental workflow for optimizing the mobile phase to achieve maximum MS sensitivity and chromatographic resolution for a hypothetical drug in plasma.

Objective: To establish the optimal mobile phase composition (organic modifier, buffer pH, and additive) for the LC-MS/MS quantification of [Drug Name] in human plasma. Materials:

- Chemicals: HPLC-grade water, acetonitrile, methanol, ammonium formate, ammonium acetate, formic acid, acetic acid, ammonia solution.

- Equipment: LC-MS/MS system with electrospray ionization (ESI) and binary pump, analytical columns (as per Table 1).

- Standards: Pure analyte standard, internal standard.

Procedure:

- Standard Solution Preparation: Prepare a stock solution of the analyte at 1 mg/mL in an appropriate solvent (e.g., DMSO, methanol). Further dilute with a 50:50 mixture of water and organic solvent to a working concentration of 1 µg/mL for direct infusion and LC-MS testing [33].

- Initial MS/MS Optimization (Direct Infusion):

- Directly infuse the standard solution into the MS to determine the precursor ion ([M+H]+ or [M-H]-) and optimize fragmentor voltage.

- Select multiple reaction monitoring (MRM) transitions, optimizing collision energy (CE) for at least two fragments per compound [33].

- Initial Chromatographic Screening:

- Column: Install a C18 column (e.g., 50-100 mm length, 2.1 mm i.d., sub-3µm particles).

- Mobile Phase A: Test 0.1% formic acid in water.

- Mobile Phase B: Test 0.1% formic acid in acetonitrile.

- Perform a fast gradient (e.g., 5% to 95% B in 3-5 minutes) to assess retention and peak shape.

- Systematic Mobile Phase Comparison:

- Using the same column and standard, test the following mobile phase systems in an identical gradient:

- Data Analysis: For each system, record and compare the peak area (indicator of ionization efficiency), peak asymmetry factor, signal-to-noise ratio at the lower limit of quantification (LLOQ), and retention time stability.

The following workflow diagram summarizes this experimental protocol for mobile phase optimization:

Case Study: LC-MS/MS Method for Omadacycline in Human Plasma

A recent study developed an LC-MS/MS method for quantifying omadacycline, an antibiotic, in human plasma, providing an excellent real-world application of these principles [14].

Chromatographic Conditions:

- Column: Phenomenex KINETEX XB-C18 (50 x 3.0 mm, 2.6 µm).

- Mobile Phase: A: 0.1% Formic acid in water; B: Acetonitrile.

- Gradient Elution:

- 0-0.5 min: 10% B

- 0.5-3.5 min: 10% B → 95% B

- 3.5-4.0 min: 95% B

- 4.0-4.1 min: 95% B → 10% B

- 4.1-5.0 min: 10% B (re-equilibration)

- Flow Rate: 0.4 mL/min.

- Column Temperature: 40°C.

- Injection Volume: 5 µL.

- Total Run Time: 5 minutes.

Mass Spectrometry Conditions:

- Ionization: Electrospray Ionization (ESI), Positive Ion Mode.

- MRM Transitions:

- Omadacycline: m/z 557.4 → 453.4

- Internal Standard (Fexofenadine-d6): m/z 508.4 → 472.8

Sample Preparation: Protein precipitation was employed using 200 µL of acetonitrile (containing the internal standard) added to 50 µL of plasma. After vortexing and centrifugation, the supernatant was diluted with 0.1% formic acid in water and injected [14].

Key Outcomes: The method demonstrated linearity from 20-2000 ng/mL, with precision (RSD) <10% and accuracy (RE) within ±10%, successfully applied to clinical therapeutic drug monitoring.

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table details key reagents and materials essential for successful LC-MS/MS method development for plasma analysis.

Table 3: Essential Research Reagents and Materials for LC-MS/MS Plasma Method Development

| Item Category | Specific Examples | Function & Application Notes |

|---|---|---|

| HPLC Columns | C18, C8, Phenyl-Hexyl, HILIC (e.g., silica, amide) | Stationary phase for chromatographic separation; selection is critical for retention and selectivity [14] [29]. |

| Organic Solvents | Acetonitrile, Methanol (HPLC-MS Grade) | Mobile phase organic modifiers; high-purity grade is essential to minimize background noise [27] [31]. |

| Volatile Buffers | Ammonium Formate, Ammonium Acetate | Provide pH control and buffering capacity in the mobile phase while being compatible with MS detection [32] [28]. |

| Ionization Additives | Formic Acid, Acetic Acid, Ammonia Solution | Enhance analyte ionization in the ESI source and can improve chromatographic peak shape [14] [32] [30]. |

| Sample Prep Sorbents | C18, Mixed-Mode Cation/Anion Exchange | Used in Solid-Phase Extraction (SPE) for clean-up and concentration of analytes from complex plasma matrix [29]. |

| Protein Precipitants | Acetonitrile, Methanol, Trichloroacetic Acid | Used in protein precipitation to remove proteins from plasma samples prior to analysis [14] [5]. |

| Internal Standards | Stable Isotope-Labeled Analogs (e.g., d6, 13C) | Correct for variability in sample preparation and ionization efficiency; ideal for quantification [14] [30]. |

| KB02-JQ1 | KB02-JQ1, CAS:2384184-44-3, MF:C38H43Cl2N7O6S, MW:796.77 | Chemical Reagent |

| Cyclo(his-pro) TFA | Cyclo(his-pro) TFA, MF:C13H15F3N4O4, MW:348.28 g/mol | Chemical Reagent |

Troubleshooting and Best Practices

Even with a systematic protocol, challenges can arise. The following diagram illustrates a logical troubleshooting path for common chromatographic issues, linking them back to potential root causes in column or mobile phase selection.

Additional Best Practices:

- Mobile Phase Preparation: Always use the highest purity water and solvents. Measure pH of the aqueous buffer before adding the organic solvent. Filter and degas all mobile phases to prevent blockages and baseline noise [27].

- Column Care: Use a guard column to protect the analytical column. Flush and store columns according to the manufacturer's instructions to maximize their lifetime.

- System Suitability: Always perform system suitability tests before a batch run to ensure the method is performing as expected in terms of retention, resolution, peak shape, and sensitivity.

The path to a robust and sensitive LC-MS/MS method for quantifying drugs in plasma is a deliberate process of optimization. It begins with a rational selection of the chromatographic column based on analyte chemistry, followed by meticulous optimization of the mobile phase—its organic modifier, pH, and additives—to achieve the trifecta of strong retention, excellent peak shape, and maximum MS signal intensity. By adhering to the structured protocols, case study examples, and troubleshooting guidance provided in this application note, researchers and drug development professionals can enhance the efficiency and success of their bioanalytical method development, thereby generating high-quality data that is critical for advancing pharmaceutical science.

In the development of LC-MS/MS methods for quantifying drug concentrations in plasma, sample preparation is a critical first step to ensure the accuracy, sensitivity, and reliability of bioanalytical results. Effective sample preparation removes interfering matrix components, concentrates the analyte, and protects the instrumentation, thereby enhancing data quality [34] [29]. For researchers and drug development professionals, selecting the appropriate sample preparation technique is paramount for obtaining meaningful pharmacokinetic and toxicokinetic data.

Among the various available methods, protein precipitation (PP) and liquid-liquid extraction (LLE) are two widely used approaches for processing biological samples like plasma and serum. This application note provides a detailed comparison of these two techniques, framed within the context of developing a robust LC-MS/MS method for drug quantification in plasma. We summarize quantitative performance data, provide detailed experimental protocols, and offer guidance for method selection to support your bioanalytical workflows.

Core Principles and Comparative Analysis

Protein Precipitation is a straightforward and rapid deproteinization method. It involves adding a miscible organic solvent (e.g., methanol, acetonitrile, or acetone) to the plasma sample. The solvent disrupts the hydration shell around proteins, causing them to denature and aggregate, after which they are removed by centrifugation [34] [35]. This technique is characterized by its simplicity, minimal method development requirements, and high-throughput capability, making it particularly suitable for the early stages of drug discovery [34] [36].

Liquid-Liquid Extraction, in contrast, is a more selective technique that separates analytes based on their differential solubility between two immiscible liquid phases, typically an aqueous phase (the plasma sample) and an organic solvent [35]. The success of LLE depends on the careful selection of an organic solvent that provides optimal partitioning of the target analyte away from matrix interferences. This method often results in cleaner extracts and can significantly reduce matrix effects, which is crucial for achieving lower limits of quantification [37] [38].

Table 1: Comparative Analysis of Protein Precipitation and Liquid-Liquid Extraction

| Feature | Protein Precipitation (PP) | Liquid-Liquid Extraction (LLE) |

|---|---|---|

| Basic Principle | Denaturation and removal of proteins via organic solvents [34] | Partitioning of analyte between immiscible aqueous and organic phases [35] |

| Complexity & Workflow | Simple and fast; minimal method development [34] | More complex; requires solvent selection and optimization [37] |

| Typical Solvents | Acetonitrile, Methanol, Acetone [34] [39] | Methyl tert-butyl ether (MTBE), Ethyl acetate, Chloroform, Hexane [37] [40] |

| Matrix Removal | Moderate; some phospholipids and salts may remain [41] | Excellent for removing polar matrix interferences and phospholipids [37] |

| Recovery | Generally high and consistent for small molecules [34] | Can be very high, but highly dependent on analyte and solvent choice [37] |

| Throughput | High, easily automated in 96-well plates [36] | Lower, though automation with 96-well plates is possible [40] |

| Ideal Use Case | High-throughput screening, early drug discovery [34] | Targeted quantification requiring high sensitivity and low matrix effects [37] |

Detailed Methodologies and Protocols

Protein Precipitation Protocol

This protocol for protein precipitation using acetonitrile is adapted for a high-throughput 96-well format and is suitable for processing plasma samples in pharmacokinetic studies [36].

Materials and Reagents:

- Acetonitrile (LC-MS grade)

- Formic acid (LC-MS grade)

- Internal Standard working solution

- Plasma samples

- 96-well protein precipitation or filtration plate (e.g., PTFE membrane)

- 96-well collection plates

- Centrifuge capable of handling microplates

- Positive displacement liquid handler (optional, for automation)

Procedure:

- Aliquot Samples: Pipette 50 µL of acidified acetonitrile (containing 0.1% formic acid and the internal standard) into each well of a 96-well filtration plate.

- Add Plasma: Add 25 µL of plasma sample to the corresponding wells.

- Mix: Seal the plate and vortex mix for 3-5 minutes to ensure complete protein precipitation.

- Separate: Centrifuge the stacked plate (filtration plate on top of a collection plate) at approximately 1,500 × g for 5-10 minutes. The vacuum or centrifugal force will drive the deproteinized supernatant through the filter into the collection plate.

- Analyze: Transfer an aliquot (e.g., 10 µL) of the clear supernatant from the collection plate directly to an LC-MS/MS system for analysis [36].

Variations: Methanol and acetone are also commonly used precipitating solvents. A study comparing five different precipitation methods found that methanol and methanol/acetonitrile mixtures provided broad specificity and outstanding accuracy for metabolomics applications, a finding that is often transferable to small-molecule drug analysis [41]. For urine proteomics, methanol/chloroform precipitation has been shown to provide high protein recovery rates and a large number of protein identifications in LC-MS/MS analysis [39].

Liquid-Liquid Extraction Protocol

This LLE protocol uses methyl tert-butyl ether (MTBE) for the extraction of a pharmaceutical compound from whole blood, which can be readily adapted for plasma samples [40].

Materials and Reagents:

- Methyl tert-butyl ether (MTBE, HPLC grade)

- Internal Standard working solution in methanol/water

- Plasma samples

- 2 mL 96-well deep-well plates

- Centrifuge

- Liquid handler (recommended for automation)

- Nitrogen evaporator

Procedure:

- Internal Standard & Lysis: Add 60 µL of internal standard working solution to a 2 mL 96-well plate. The aqueous-organic mixture helps to lyse any blood cells if present. Add 40 µL of plasma sample to each well and vortex for 10 minutes.

- Extraction: Add 500 µL of MTBE to each well. Seal the plate securely and mix thoroughly by vortexing for 10-20 minutes to achieve efficient partitioning of the analyte into the organic phase.

- Phase Separation: Centrifuge the plate at a sufficient speed (e.g., 3,000 × g) for 10 minutes to achieve clear phase separation.

- Collection: Carefully collect 450 µL of the upper organic layer and transfer it to a new 96-well plate. Take care not to disturb the interface or the lower aqueous layer.

- Evaporation and Reconstitution: Evaporate the organic solvent to dryness under a gentle stream of nitrogen. Reconstitute the dried extract with 180 µL of a solvent compatible with your LC-MS/MS mobile phase (e.g., 20/80 acetonitrile/water) with vortex mixing.

- Analyze: Inject an aliquot (e.g., 20-30 µL) into the LC-MS/MS system [40].

Notes on Solvent Selection: The choice of organic solvent is critical. Dibutyl phthalate has been shown to provide complete extraction of compounds like testosterone and phenytoin from buffer solutions, though recovery from protein-containing matrices like albumin may be partial [37]. For extracting diverse compounds from traditional Chinese medicine, an ethyl acetate:acetone (10:1) system has proven effective [38].

Workflow Visualization

The following diagram illustrates the key decision points and procedural steps involved in selecting and executing PP or LLE for plasma sample preparation.

Essential Research Reagent Solutions

The selection of appropriate reagents is fundamental to the success of any sample preparation method. The following table details key materials and their functions in PP and LLE protocols.

Table 2: Key Reagents and Materials for Sample Preparation

| Reagent/Material | Function | Application Notes |

|---|---|---|

| Acetonitrile (LC-MS Grade) | Protein precipitating agent. Denatures and aggregates plasma proteins for easy removal [34]. | Most common precipitant; provides clean backgrounds. Acidification with 0.1% formic acid can improve recovery for some analytes [36]. |

| Methanol (LC-MS Grade) | Protein precipitating agent and solvent for standards/reconstitution [34] [40]. | Especially valuable for supporting preclinical pharmacokinetic studies during lead optimization [34]. |

| Methyl tert-butyl ether (MTBE) | Organic extraction solvent for LLE [40]. | A volatile and relatively safe solvent. Provides high recovery for non-polar to moderately polar analytes [40]. |

| Formic Acid (LC-MS Grade) | Mobile phase additive and solvent acidifier. Enhances protonation of analytes in positive ESI mode [36]. | Improves ionization efficiency and peak shape. Commonly used at 0.1-0.2% in mobile phases and sample solvents [36]. |

| Internal Standards | Isotope-labeled analogs of the analyte(s). Correct for variability in sample preparation and ionization [40]. | Crucial for achieving accurate and precise quantification. Should be added at the very beginning of the sample preparation process. |

| 96-Well Filtration Plates (PTFE) | For high-throughput protein precipitation. Membrane retains precipitated proteins during filtration [36]. | Enables parallel processing of 96 samples, eliminating the need for manual supernatant transfer and increasing reproducibility [36]. |

| Ammonium Acetate/Formate | Buffering agents for mobile phases. Can promote adduct formation ([M+NHâ‚„]âº) [40]. | Useful for stabilizing certain analytes. Concentration (e.g., 5-10 mM) and compatibility with MS detection should be optimized. |

Both protein precipitation and liquid-liquid extraction are indispensable techniques in the bioanalytical toolkit for LC-MS/MS-based drug quantification in plasma. The choice between them is not a matter of superiority but of strategic fit. Protein precipitation offers unmatched speed and simplicity, ideal for high-throughput environments like early drug discovery. Liquid-liquid extraction, while more labor-intensive, provides superior sample clean-up and reduced matrix effects, making it the method of choice for assays requiring high sensitivity and rigorous validation, such as those supporting late-stage development and clinical trials.

Researchers are advised to base their selection on key project parameters, including the number of samples, required throughput, physicochemical properties of the analyte, and the desired level of sensitivity. In many cases, a complementary use of both techniques—employing PP for rapid screening and LLE for definitive analysis—can provide an efficient and effective strategy across the drug development pipeline.

In the development of a robust Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS) method for quantifying drug concentrations in plasma, the optimization of mass spectrometric parameters is a critical step that directly impacts method sensitivity, selectivity, and reproducibility. The process specifically focuses on two key areas: the ion source, where analyte molecules are converted into gas-phase ions, and the collision cell, where precursor ions are fragmented into product ions for detection [42] [43]. This application note provides detailed protocols and strategic frameworks for systematically optimizing these parameters to enhance bioanalytical performance in pharmaceutical research and development.

Efficient method development requires understanding the role of each parameter in the MS workflow. The figure below illustrates the key optimization parameters in a triple quadrupole mass spectrometer and their locations within the system.

Figure 1. LC-MS/MS optimization parameters. This workflow shows the key parameters for ion source and collision cell optimization in a triple quadrupole mass spectrometer.

Ion Source Parameter Optimization

The ion source converts analyte molecules into gas-phase ions, with efficiency determined by multiple interdependent parameters. Systematic optimization of these parameters significantly enhances ionization efficiency and overall signal response [44] [43].

Critical Ion Source Parameters and Their Functions

Table 1. Key Ion Source Parameters for Optimization in ESI Mode

| Parameter | Symbol | Function | Typical Range | Optimization Impact |

|---|---|---|---|---|

| IonSpray Voltage | IS | Creates strong electric field for droplet charging and ion emission | 2000-6000 V | Dramatically affects ionization efficiency; optimal voltage is compound-dependent [43] |

| Nebulizer Gas | GS1 | Shears liquid stream into fine droplets for efficient desolvation | 0-150 psi | Higher values create smaller droplets but excessive flow can cool spray [43] |

| Heating Gas | GS2 | Promotes desolvation of charged droplets through heated nitrogen flow | 0-150 psi | Prevents solvent clusters; temperature should be optimized with TEM [43] |

| Source Temperature | TEM | Controls heating of auxiliary gas for enhanced desolvation | 100-700°C | Critical for highly aqueous mobile phases; prevents premature vaporization [43] |

| Curtain Gas | CUR | Forms barrier between source and analyzer; prevents contamination | 0-50 psi | Higher values reduce chemical noise; optimize without significant sensitivity loss [43] |

| Declustering Potential | DP | Accelerates ions to remove solvent adducts and clusters | 20-200 V | Balances between adduct removal and unwanted in-source fragmentation [43] |

| Entrance Potential | EP | Guides and focuses ions through Q0 region | 5-15 V | Minor effect on optimization; typically set at ±10 V [43] |

Experimental Protocol for Ion Source Optimization

Sample Preparation for Optimization

- Prepare a pure chemical standard of the target analyte at concentrations typically ranging from 50 ppb to 2 ppm in an appropriate solvent [33]. For drug quantification in plasma, omadacycline was optimized using standards at 20-2000 ng/mL in blank plasma [45].

- Use a solvent composition that matches the anticipated mobile phase (typically 50:50 organic:aqueous ratio) to maintain consistency between optimization and final method conditions [33] [43].

- For plasma-based methods, include matrix-matched quality control samples at low, medium, and high concentrations to monitor matrix effects during optimization [45].

Systematic Optimization Procedure

- Step 1: Sample Introduction: Utilize either infusion (5-25 μL/min via syringe pump) or flow injection analysis (FIA) (25-1000 μL/min via LC system) to introduce the standard to the mass spectrometer without chromatographic separation [43].

- Step 2: IonSpray Voltage and Gas Optimization: Using MRM mode, systematically vary IS voltage while monitoring signal response. Subsequently, optimize GS1, GS2, TEM, and CUR parameters using a multivariate approach [44] [43].

- Step 3: Declustering Potential Optimization: Introduce the standard and perform a Q1 scan to determine the optimal DP value (typically 20-100 V) that maximizes precursor ion intensity while minimizing fragmentation [43].

- Step 4: Response Surface Methodology (RSM): For advanced optimization, employ design of experiments (DoE) approaches to model interaction effects between parameters. This has been shown to improve signal-to-noise ratios 2-4 fold for challenging analytes [46].

Collision Energy Optimization

Collision energy optimization determines the efficiency of precursor ion fragmentation into characteristic product ions, directly impacting the selectivity and sensitivity of MRM-based quantification methods [33] [43].

Collision Cell Parameters and Functions

Table 2. Key Collision Cell Parameters for MRM Optimization

| Parameter | Symbol | Function | Optimization Consideration |

|---|---|---|---|

| Collision Energy | CE | Accelerates precursor ions into collision gas; determines degree of fragmentation | Compound-specific; must be optimized for each MRM transition [43] |

| Collision Gas | CAD | Inert gas (typically argon or nitrogen) for collision-induced dissociation | Sufficient pressure needed for fragmentation; typically 1-5 mTorr [43] [46] |

| Collision Cell Exit Potential | CXP | Focuses and transmits fragment ions from collision cell to Q3 | Affects transmission efficiency; typically optimized for each transition [43] |

Experimental Protocol for Collision Energy Optimization

Product Ion Scan and MRM Development

- Step 1: Precursor Ion Selection: Using the optimized ion source parameters, introduce the standard and confirm the precursor ion mass (typically [M+H]+ or [M-H]-). Account for possible adduct formation with mobile phase additives [33].

- Step 2: Product Ion Scan: Perform product ion scans across a range of collision energies (e.g., 5-50 eV) to identify the most abundant fragment ions [43]. The example of omadacycline quantification identified the transition m/z 557.4→453.4 as optimal [45].

- Step 3: MRM Transition Selection: Select at least two MRM transitions per compound - one for quantification and another for confirmation. The ratio between these transitions should remain constant and serve as a confirmatory criterion [33].

Collision Energy Fine-Tuning

- Step 4: CE Optimization: For each MRM transition, systematically vary CE in 2-5 eV increments while monitoring product ion intensity. Optimal CE typically falls between 10-40 eV, depending on the compound and instrument [43].

- Step 5: Advanced DoE Approaches: For methods quantifying multiple analytes, employ fractional factorial designs to efficiently optimize CE across all compounds. This approach revealed distinct fragmentation behaviors between polar and apolar oxylipins, requiring class-specific optimization [46].

- Step 6: CXP Optimization: Fine-tune CXP (typically 5-25 V) to maximize transmission of product ions to the detector [43].

Integrated Workflow for Comprehensive Optimization

A systematic approach to LC-MS/MS method development ensures optimal performance for drug quantification in plasma matrices. The following workflow integrates both ion source and collision energy optimization steps.

Figure 2. LC-MS/MS parameter optimization workflow. This integrated approach systematically addresses both ion source and collision cell parameters for robust method development.

Case Studies and Applications

Omadacycline Quantification in Human Plasma

A recently developed LC-MS/MS method for omadacycline quantification exemplifies proper parameter optimization [45]. Key optimized parameters included:

- Ion source: Positive ESI mode with specific desolvation temperature and gas flows

- MRM transition: m/z 557.4→453.4 with compound-specific collision energy